A digital twin is a virtual representation of a real-world system, process, or entity produced using simulation and data technology. It is a digital depiction of the natural world that can be analyzed, tracked, and optimized.

Many different sectors, including manufacturing, construction, healthcare, and transportation, can benefit from using digital twins. They enable businesses to anticipate how a physical system or object will behave under various circumstances by simulating its behavior in a virtual environment.

Data from sensors, cameras, and other sources monitoring the system or object is usually collected to create digital twins. This data is then processed and analyzed to build a virtual model accurately representing the real-world system or object. Several advantages, including increased productivity, decreased delay, and increased safety, can be attained by using digital twins. They can also be used to test and assess novel configurations or designs before practicing them in the real world.

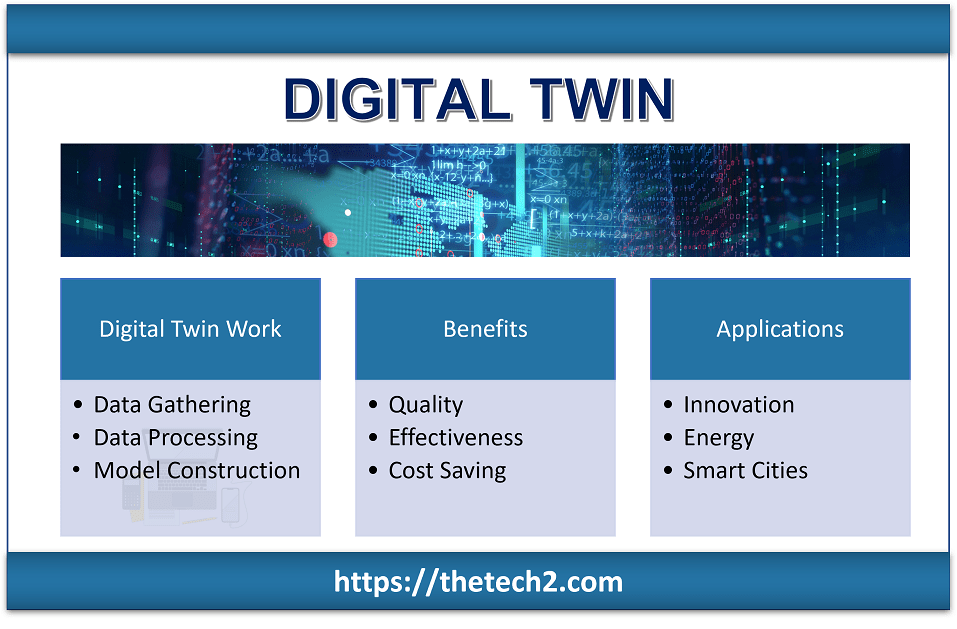

How Does a Digital Twin Work?

To model and simulate the behavior of a physical system or process, data from sensors and other sources are used to build a digital twin. Engineers and operators can keep an eye on and improve the physical system’s performance thanks to the digital twin’s real-time, dynamic perspective of the system.

A digital twin is made in several stages, including:

Data Gathering

Information about the physical system, such as temperature, pressure, vibration, and other factors, is gathered using sensors and other sources.

Data Processing

The data is processed using analytics and algorithms to build a model of the physical system’s behavior.

Model Construction

Algorithms and mathematical formulae that simulate the behavior of the physical system are used to build the model.

Simulation

Engineers and operators use the model to simulate the system’s behavior under various conditions and scenarios to evaluate and improve the physical system’s performance.

Integration

The digital twin is integrated with other methods, such as control systems and analytics tools, to provide real-time tracking and optimization of the physical system.

Types of Digital Twin

Digital twins come in a variety of forms, each of which is intended for a particular purpose or use case.

Here are a few typical types of digital twins:

- Product digital twins are used to develop, test, and improve the performance of physical products like machines and components.

- A production or industrial process digital twin maximizes productivity and quality reduces downtime, and increases safety.

- A digital twin of a system’s performance, called a “performance digital twin,” is used to track and improve performance continuously.

- A digital twin of a complete system, such as a factory or supply chain, is called a “system” and is used to optimize a system’s performance and effectiveness.

- A digital twin of an asset represents a physical asset, such as a structure or infrastructure, used to track and control its performance, upkeep, and lifecycle.

- A computerized representation of a person used to track and enhance their performance.

- Each sort of digital twin models and simulates the behavior of the physical system using data from sensors, IoT devices, and other sources. This enables engineers and operators to improve the system’s performance, cut costs, and increase safety and efficiency.

Advantages and Benefits of Digital Twin

Virtual representations of natural systems or goods are known as “digital twins,” They have several advantages. The following are some of the most important benefits of digital twins:

Enhanced Effectiveness

By examining data from physical systems and pinpointing areas for development, digital twins can optimize operational effectiveness. This enables businesses to proactively address problems and prevent downtime, eventually boosting productivity and lowering costs.

Better Quality

Digital twins allow businesses to simulate different situations and test a product’s performance before it is made. This lessens the probability of physical product defects and aids in identifying potential design flaws.

Cost Savings

Organizations can cut physical testing and maintenance expenses by using digital twins. Insights obtained from digital twins can also help cut waste and increase resource efficiency.

Predictive Maintenance

Digital twins allow businesses to track and assess the functionality of tangible systems in real-time. This enables them to conduct predictive maintenance and identify problems before they become serious, which can significantly reduce downtime and maintenance costs.

Increased Innovation

Digital twins give businesses a risk-free way to experiment with new concepts and investigate alternative outcomes. This promotes creativity and innovation, resulting in better goods and services.

Digital Twin Applications

Cost savings: Organizations can cut physical testing and maintenance expenses by using digital twins. Insights obtained from digital twins can also help cut waste and increase resource efficiency.

Predictive Maintenance

Digital twins allow businesses to track and assess the functionality of tangible systems in real-time. This enables them to conduct predictive maintenance and identify problems before they become serious, which can significantly reduce downtime and maintenance costs.

Increased Innovation

Digital twins give businesses a risk-free way to experiment with new concepts and investigate alternative outcomes. This promotes creativity and innovation, resulting in better goods and services.

Aerospace

Digital twins can evaluate various scenarios, simulate aircraft and spacecraft design, and assess performance statistics. This benefits the aerospace sector by raising efficiency, lowering expenses, and improving safety.

Energy

The efficiency of power plants and renewable energy systems can be optimized and simulated using digital twins. They can also track and examine energy use data, spot possible problems, and boost effectiveness.

Smart Cities

Digital clones can optimize and simulate urban planning and infrastructure design. They can assist engineers and city planners in identifying possible problems and enhancing the sustainability and livability of urban areas.

The Future of Digital Twin

Digital twin technology has a bright future, and over the next few years, we should expect to see several developments and innovations. The following are some of the significant trends and advancements that are most likely to influence the direction of digital twin technology:

Integration

Digital twins are expected to integrate more with other technologies, including augmented reality, the Internet of Things, and artificial intelligence (AR). This will allow for running more sophisticated simulations and conducting in-depth data analysis, improving output and efficiency.

Increased Automation

As digital twin technology develops, we can anticipate seeing an increase in the automation of decisions and procedures. Organizations can function more effectively and react to changes more rapidly.

Increasing into New Industries

Although several sectors have already adopted digital twin technology, we can anticipate its potential expansion into new sectors. Digital twins could be used, for instance, to simulate and improve supply chain operations or create fresh approaches to municipal planning.

Greater Emphasis on Sustainability

As sustainability becomes increasingly essential, digital twins will be crucial for maximizing resource usage and cutting waste. We can anticipate the development of more environmentally friendly design and refining techniques.

Personalization

Using digital twins, personalized goods and services could be created, each catering to the customer’s requirements and preferences. Digital twins could be used to model and improve processes in the healthcare industry, making this especially pertinent.

You may be interested in more Big Data topics.